Industrial Touch Panel and Industrial Panel PCs

References for Machine and Plant Engineering

Especially in harsh environments, industrial touch panels have to withstand special environmental influences. They are frequently exposed to heat, dust, vibration or moisture. The operating devices must reliably master these challenges.

This means that industrial panel PCs must also meet special requirements. The industrial panels must be robust and completely enclosed to prevent dust from entering, for example, or to ensure good cleanability. It must also be ensured that no liquids can get inside.

We have a wide range of different industrial touch panel solutions. The advantage lies in an extensive range of components. The touch panels can thus be configured for a wide variety of requirements in machine and plant engineering. If the standard range is still not sufficient, we will work with you to develop exactly the solution that suits you.

Advantages of Industrial Touch Panel Solutions from Christ

- Robust construction for use of the panels in harsh industrial environments

- Planning reliability for machine builders thanks to long-term available components

- Modular configuration allows great scope for individual solutions

- OEM solutions as fully customized panel solutions

- Industrial touch panels are ideally suited for HMI and machine operation

Industrial Touch Panel References

A modular solution without thinking of keys

A comprehensive set of specifications for the hardware and software for operating the facilities by means of intuitive and individualized operating apps was created from the construction kit of operating variants. Operation was to take place via a freely configurable web user interface (web UI). Due to the desired consistency, its design was based on the proven main control consoles of TRUMPF machines. The number of places for real keys was small - on purpose. Only absolutely necessary keys, such as the classic emergency stop key and the enabling key for 2-hand control, were a fixed component. Additional keys could be inserted as needed by removing a dummy plug from a hole.

Read the full report now for free.

Lieberr-Verzahntechnik GmbH

Mobile and stationary touch panels define a new era of machine operation

Lieberr-Verzahntechnik GmbH, based in Kempten, Germany, offers its customers high-performance machine and software solutions to produce a wide variety of gears in a process-safe manner

Liebherr-Verzahntechnik GmbH, based in Kempten, Germany, offers its customers high-performance machine and software solutions for the reliable production of a wide variety of gears.

Two touch panels for optimum machine operation

The company wanted to improve the operation of its gear cutting machines with a new control panel. An important requirement was separate operating units between a stationary operating panel and a mobile handheld unit. This would allow machine operators to get closer to the process and simplify operation. The design also needed to be new and more intuitive to realize an excellent user experience (UX).

Tight schedule - no problem for Christ

Christ was commissioned in the first step to produce prototypes in just 23 weeks, an extremely time-critical project. The devices were to be ready for the world's leading trade show, EMO. Find out what technical challenges the touch panels have to overcome and whether everything was finished on time in our Success Story!

Read the full report now for free.

Trumpf Laser GmbH

High Performance Touch Panel from Christ Provide Technology for Real-Time Image Processing Vision Line

When the real-time VisionLine image processing system was to enter volume production, Trumpf - the world's leading supplier of highly integrated laser manufacturing solutions - switched to Christ industrial touch panels.

The decisive factors for this were the know-how and flexibility of the HMI specialist, as well as the robustness and acceptance of the panels in rough industrial use.

"With Christ, we were able to successfully bring our image processing solution into series production in the required quality and quantity. The compact panels with their high-quality manufactured aluminum housings fit perfectly with Trumpf's strong appearance."

says Mr. Thieringer, head of software development at Trumpf Laser, Schramberg.

Industry touch panels must perform high-performance computing and provide real-time image processing. For years, the cooperation between the two companies has been developing. In the meantime, all of Trumpf's development departments in Germany and Switzerland work together with Christ.

Industrial panels in marking systems

Industrial Panel PCs are used to control cameras in Trumpf marking systems, which can be located directly behind the scanner lens or mounted on the side. Using the Autofocus function, the panel calculates the optimum working distance - with an accuracy of between ±50 to ±150 μm. This alone greatly reduces setup times and fixture requirements. "Medical components, for example, can be marked immediately like bulk material - without the need for complex fixtures," shares Mr. Thieringer. The traceability function recognizes the previously applied component code, ensuring that the code is later readable and correct.

Read the full report now for free.

Ersa GmbH

Touch panel for electronics manufacturing

Ersa GmbH is an electronics pioneer with an extensive product portfolio featuring sustainable energy-efficient production processes and automation solutions.

Ersa wanted to celebrate its 100th anniversary at Productronica 2021 by presenting a new generation of its reflow soldering system and ushering in a new era.

Industrial PC replaces Desktop PC

In the future, Ersa will use industrial touch panel PCs for their new generation of systems. The advantage lies in the long-term availability of the parts and a high-quality overall impression.

Among five candidates, the decision was ultimately made in favor of the Automation Panels from Christ. Read the reference report to find out which reasons were decisive and which advantages Ersa sees in a cooperation with Christ.

Read the full report now for free.

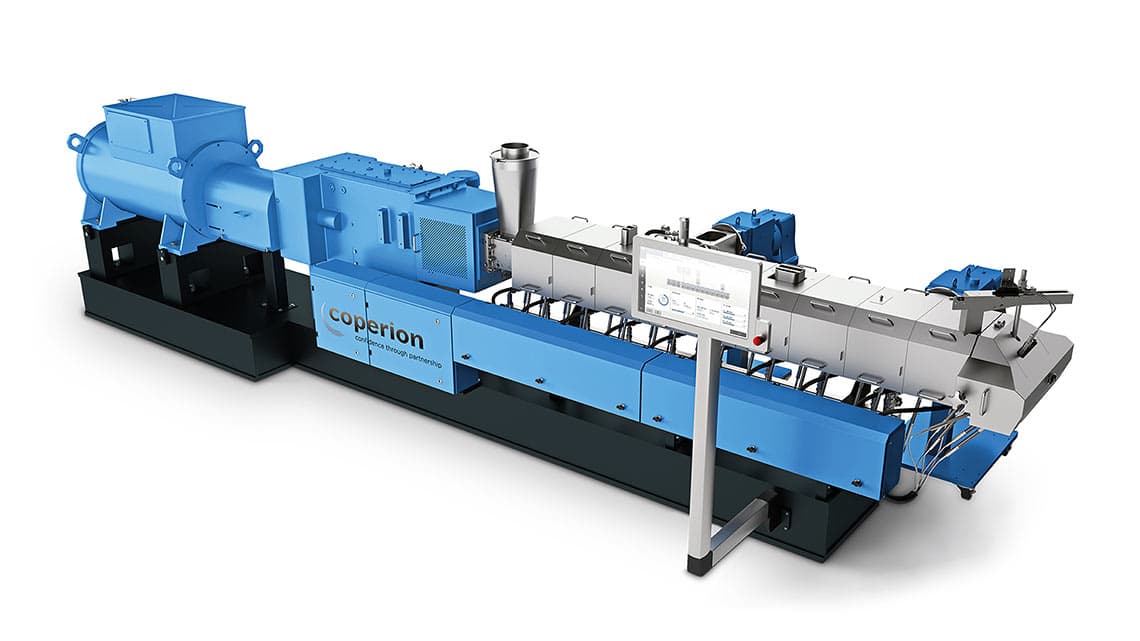

Coperion GmbH

Remote monitor solutions for large extruder lines

Company:

Coperion GmbH is a global leader in compounding and extrusion, feeding and weighing technology, bulk materials handling and related services.

Project description:

The challenge in extruder technology is the size of the systems. In some cases, these are set off over more than 50 meters from the central control cabinet.

With the SMART Distance Link technology from the house of Christ Electronic Systems GmbH, the operation of these extended plants is guaranteed even over long distances.

Challenges:

- Guaranteeing the transmission of signals over long distances.

- Development of an OEM operating panel with direct machine operation

Special features:

- Coperion was a beta customer with regard to product development. The company gave Christ the chance to deliver and test the system before it was fully completed.

Technical information:

- The SMART Distance Link solution is available in the same look both as a surface-mounted solution and as a built-in panel.

Advantages of the solution:

- The SMART Distance Link unit uses the TCP-IP standard

Features:

- Coperion was a beta customer in terms of product development. The company gave Christ the chance to deliver and test the system before it was fully completed.

Technical information:

- The SMART Distance Link solution is available in the same look as both a surface-mounted solution and a built-in panel.

Advantages of the solution:

- The SMART Distance Link unit uses the TCP-IP standard .

You are looking for more information about Industrial Touch Panels

We will be happy to advise you - free of charge and without obligation

Industrial touch panel for machinery and equipment

Are you looking for a suitable solution for your machine or plant? Or do you still have questions about our industrial touch panel solutions?

We are happy to advise you free of charge and without obligation. Together, we will find the right solution for your application.

Just fill out the form, we will get back to you as soon as possible! We look forward to hearing from you.

Display solutions in the industry for mechanical and plant engineering

Touch panels must withstand special environmental influences, especially in industrial environments. They are often exposed to heat, dust, vibration or moisture. The operating devices must reliably master these challenges. This means that the housing must also meet special requirements. Touch Panels in industry must have a robust and completely closed design, for example to prevent dust from entering or to ensure good cleanability. Industrial touch panels are often used in environments where they come into contact with dust or liquids. To ensure proper operation, the displays must be easy to clean and of course prevent foreign matter from entering the interior of the devices.

Industrial touch panel solutions with multi-touch and glove operation

The standard use of multitouch and gesture control helps to avoid mistakes due to incorrect touch. This makes a major contribution to process optimization and avoidance of production downtime due to operator error. In many industrial plants, gloves are used. Nevertheless, machine operation must be ensured. Operating errors can be reduced by touch calibration behavior to the gloves used.

Industrial touch screen: Mechanical operating elements and OEM devices

In many machines and systems, mechanical elements such as buttons are required in addition to the touch panel to implement certain functions (e.g. the emergency stop as a standardized function). Here the panel is supplemented by a push-button extension, which can then be configured individually. In order to match the design of the machine or plant, it may happen that the standard versions of the housings do not fit into the existing machine concept or do not correspond to the design draft of a new plant. By designing OEM devices, both design and performance requirements can be tailored even more individually to the respective demands. The machines and systems are usually in use for many years. For this reason, long-term availability of the touch panels and the individual components is particularly important to prevent production downtimes. These cost manufacturing companies a lot of money quickly.

Performance classes of industrial touch panels

Every machine and every plant has different requirements for the HMI. For example, powerful panel PCs or compact web panel solutions can be used. For particularly large systems, signals can be transmitted over long distances with the help of a remote variant. The touch panel monitors can also be used as display solutions on the machines.

Touch panel solutions and digitalization in industry

The demands on machine control systems are becoming increasingly complex. Data from the PLC enable monitoring of the machine status and, if necessary, trigger actions by the machine operator. The real-time availability of data and the networking of individual machines and systems in terms of Industry 4.0 and IIoT solutions is becoming increasingly important. For this reason, the corresponding applications for monitoring and machine control are also becoming more extensive and more demanding.

This might also interest you:

Automation Touch Panel

Touch Panel development

Front Panel